Chaena theko e tlase e bonolo e lutseng Swing Check Valve

Ka lebaka la thuso e ntle haholo, mefuta e fapaneng ea lihlahisoa le litharollo tsa boleng bo holimo, litšenyehelo tse matla le phano e sebetsang hantle, re thabela botumo bo botle har'a bareki ba rona. Re khoebo e mafolofolo e nang le 'maraka o pharaletseng oa Chaena oa theko e tlase. Re reka ho holisa 'maraka oa rona oa machabeng, haholo-holo re fana ka bareki ba rona ba kantle ho naha. Lintho tsa boleng bo holimo le thuso.

Ka lebaka la thuso e ntle haholo, mefuta e fapaneng ea lihlahisoa le litharollo tsa boleng bo holimo, litšenyehelo tse potlakileng le phano e sebetsang hantle, re thabela botumo bo botle har'a bareki ba rona. Re khoebo e mafolofolo e nang le 'maraka o pharaletseng oaValve ea Chaena le Valve ea Serurubele, Re ntse re eketsa karolo ea rona ea 'maraka oa machaba ho latela lihlahisoa tsa boleng bo holimo, tšebeletso e ntle haholo, theko e utloahalang le ho tlisoa ka nako. Ka kopo ikopanye le rona neng kapa neng bakeng sa tlhaiso-leseling e batsi.

Qaqiso ea Sehlahisoa

| Boholo le Tekanyetso ea Khatello le Maemo a Tloaelehileng | |

| Boholo | DN50-DN600 |

| Tekanyetso ea Khatello | PN6,PN10, PN16, CL150-600 |

| Sefahleho se talimane le STD | API609, BS5155, DIN3202, ISO5752 |

| Khokahano ea STD | PN6, PN10, PN16, DIN 2501 PN6/10/16, BS5155 |

| Thepa | |

| 'Mele | Tšepe e entsoeng ka tšepe (GG25), Tšepe e entsoeng ka tšepe (GGG40/50), Tšepe ea khabone (WCB A216), Tšepe e sa ruseng (SS304/SS316/SS304L/SS316L), Tšepe e sa ruseng e entsoeng ka tšepe e habeli (2507/1.4529), Boronse, Aluminium Alloy. |

| Disiki | DI+Ni, Tšepe ea Khabone (WCB A216), Tšepe e sa Ruseng (SS304/SS316/SS304L/SS316L), Tšepe e sa Ruseng e habeli (2507/1.4529), Boronse, DI/WCB/SS e koahetsoeng ka Epoxy Pente/Nylon/EPDM/NBR/PTFE/PFA |

| Kutu/Mokoti | SS416, SS431, SS304, SS316, Tšepe e sa hloekang ea Duplex, Monel |

| Setulo | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA |

Pontšo ea Sehlahisoa

Molemo oa Sehlahisoa

Valve ea ho hlahloba, e tsejoang hape e le valve ea tsela e le 'ngoe, valve ea ho hlahloba, valve ea khatello ea morao, mofuta ona oa valve o buloa le ho koaloa ka bohona ke matla a hlahisoang ke phallo ea medium ka boeona ka har'a phaephe, 'me ke ea valve e iketsang. Mosebetsi oa valve ea ho hlahloba ke ho thibela phallo ea medium, ho potoloha ho khutlelang morao ha pompo le enjene ea eona e khannang, le ho ntšoa ha medium ka setshelong. Valve ea ho hlahloba ea poleiti e habeli ke mofuta o tloaelehileng haholo oa valve ea ho hlahloba. Ka ho khetha thepa e fapaneng, valve ea ho hlahloba ea wafer e ka sebelisoa metsing, mouoane, oli ho petrochemical, metallurgy, motlakase, indasteri ea leseli, lijo le liindasteri tse ling. , nitric acid, acetic acid, medium e matla ea oxidizing le urea le mecha e meng ea phatlalatso.

Valve ea ho hlahloba swing e amohela sebopeho sa ho fetola letsoho sa rocker se hahiloeng kahare. Likarolo tsohle tsa ho bula le ho koala tsa valve li kentsoe ka hare ho 'mele oa valve 'me ha li kenelle 'meleng oa valve. Ntle le gasket ea ho tiisa le lesale la ho tiisa le sebelisoang flange e bohareng, kakaretso Ha ho na ntlha ea ho lutla, e felisang monyetla oa ho lutla ha valve. Khokahano pakeng tsa letsoho la rocker le disc ea valve ea ho hlahloba swing e amohela sebopeho sa khokahano e chitja, e le hore disc e be le tokoloho e itseng ho tloha ho likhato tse 360, 'me e be le puseletso e nepahetseng ea boemo ba trace. E sebelisoa haholo-holo peteroleng, lik'hemik'hale, meriana, manyolo, jj., motlakase le liphaephe tse ling. E loketse mecha e hloekileng, ha e loketse mecha e nang le likaroloana tse tiileng le viscosity e phahameng

Lihlahisoa tse Rekisang ka Cheseho

5k 10k Wafer Butterfly Valve

Valve ea Tlhahlobo ea Lipoleiti tse peli

Valve ea Heke ea Stem e sa ntseng e phahama

Valve ea ho Hlahloba ea Rubber ea Ulu

Valve ea Serurubele sa Lug

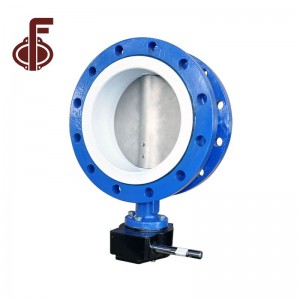

Flange Butterfly Valve

Thipa Heke Valve

Welded Ball Valve

Sesepa sa Y

Ka lebaka la thuso e ntle haholo, mefuta e fapaneng ea lihlahisoa le litharollo tsa boleng bo holimo, litšenyehelo tse matla le phano e sebetsang hantle, re thabela botumo bo botle har'a bareki ba rona. Re khoebo e mafolofolo e nang le 'maraka o pharaletseng oa Chaena oa theko e tlase. Re reka ho holisa 'maraka oa rona oa machabeng, haholo-holo re fana ka bareki ba rona ba kantle ho naha. Lintho tsa boleng bo holimo le thuso.

Chaena Theko e tlaseValve ea Chaena le Valve ea Serurubele, Re ntse re eketsa karolo ea rona ea 'maraka oa machaba ho latela lihlahisoa tsa boleng bo holimo, tšebeletso e ntle haholo, theko e utloahalang le ho tlisoa ka nako. Ka kopo ikopanye le rona neng kapa neng bakeng sa tlhaiso-leseling e batsi.