Valve ea serurubele e feta litekong tse ngata ho tloha tlhahisong ho ea thomellong ho netefatsa boleng le ts'epo ea eona. Tlhahlobo e felletseng e akaretsa lintho tse tloaelehileng tse kang thepa, ho koahela, ponahalo, rabara, khatello le litekanyo, hammoho le ts'ebetso ea ho koala, ponahalo, torque, thatafalo, botenya, kopano, ho nepahala ha khoele le flange, le matšoao a ho latela.

Ts'ebetso ea tlhahlobo e ka etsoa ka tatellano e latelang: Tlhahlobo ea thepa e tala → Tlhahlobo ea ts'ebetso → Teko ea ts'ebetso ea sehlahisoa se felileng → Kamohelo ea ho qetela. Karolo ka 'ngoe e hlalosoa hammoho le mekhoa le maemo a itseng.

Mokhoa oa Tlhahlobo ea Valve ea Serurubele

1. Tlhahlobo ea Lisebelisoa tse Tala

1.1 Morero

Ho netefatsa hore thepa e tala e kang 'mele oa valve, poleiti ea valve, kutu ea valve le lesale la ho tiisa li fihlela litlhoko tse tloaelehileng.

1.2 Lintho tsa Tlhahlobo:

-Tlhahlobo ea Sebopeho sa Lik'hemik'hale: U sebelisa mokhoa oa tlhahlobo ea spectrometer kapa lik'hemik'hale, netefatsa setifikeiti sa thepa ho netefatsa ho latela maemo a thepa a ASTM/GB/EN.

-Teko ea Tshebetso ea Mekaniki: Ho etsa disampole bakeng sa liteko tsa ho tsikinyeha, ho ikatisa, ho lelefatsa le ho ama.

-Tlhaloso le ho Latela Lintho: Sehlopha se seng le se seng sa thepa e tala se lokela ho khetholloa ka nomoro ea sona ea sebōpi ho netefatsa hore na tšimoloho ea sona e ka latelwa.

-Tlhahlobo ea Metallographic (Boikhethelo): Hlahloba li-castings bakeng sa liphoso tse kang ho kenyeletsoa ha slag le masoba.

2. Tlhahlobo ea litekanyo

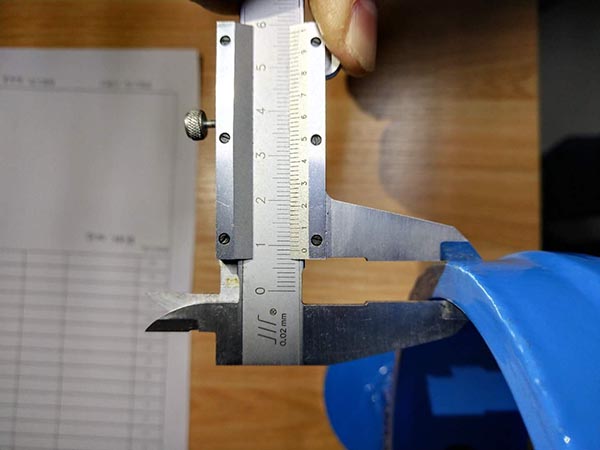

Lisebelisoa: Li-caliper tsa Vernier, gauge ea bophara ba kahare, gauge ea botebo.

2.1 Morero

Ho netefatsa hore litekanyo tsa sehlahisoa li lumellana le litšoantšo tse tloaelehileng bakeng sa ho kenya habonolo le ho fapanyetsana.

2.2 Lintho tsa Tlhahlobo

Bolelele ba 'mele oa valve (tekanyo ea lifahleho li talimane)

Sebaka sa ho hokela ha lesoba la Flange, bophara ba lesoba, tlhaloso ea khoele

Botenya ba poleiti ea valve le sebaka sa ho hlakola moeli

Botebo ba khoele le mamello

3. Tlhahlobo ea Rabara le Litulo

Lisebelisoa tse Tloaelehileng: EPDM, NBR, VITON, PTFE.

3.1 Morero

Ho netefatsa khanyetso ea khatello, khanyetso ea mocheso, le khanyetso ea mafome ea thepa ea ho koala.

3.2 Lintho tsa Tlhahlobo

Netefatso ea Lintho

Hlahloba hore bokaholimo bo boreleli, hore na ha ho na li-burrs, li-bubble le litšila.

Hlahloba litekanyo tsa bohlokoa tsa lesale la ho tiisa, tse kang bophara ba karolo e tšekaletseng le bophara ba kahare le kantle.

Bothata ba rabara (Teko ea bothata ba lebōpo), sete ea khatello, matla a ho thaepa, jj.

Teko ea ho hanyetsa ho ruruha

Ho lekana le botšepehi ba poleiti ea valve

4. Tlhahlobo ea ho koahela

4.1 Morero

Ho netefatsa hore ho hanyetsa ho bola, ho khomarela le botenya ba ho roala li fihlela litekanyetso.

4.2 Lintho tsa Tlhahlobo

Tekanyo ea pele ho phekolo ea bokaholimo (ho tlosa mafome) pele ho fafatsa (Sa2.5 kapa ho feta, ha ho na sekala kapa mafome a bonahalang)

Botenya ba ho koahela ka mor'a ho fafatsa (ho sebelisoa sekala sa botenya ba ho koahela)

Ho khomarela ho koahela (teko ea ho khaola ka sefapano, sebaka sa 1mm, sebaka sa ho petsoha ha ho koahela ≤5% kamora ho tlosoa ha theipi)

Tlhahlobo ea ponahalo (maqeba, masoba a pinhole, lipululana, lekhapetla la lamunu, phapang ea 'mala)

Teko ea ho fafatsa letsoai ka thata le ho hanyetsa mafome

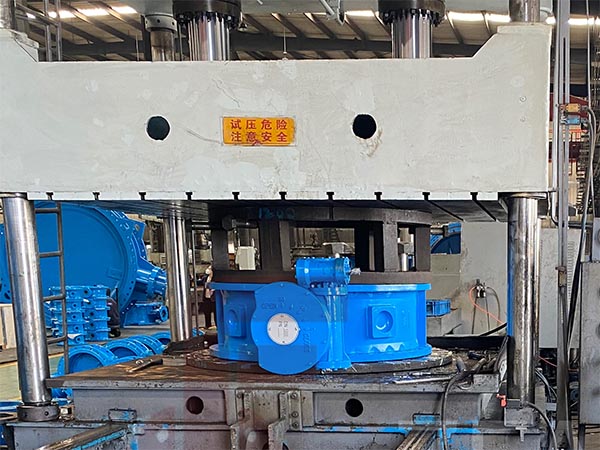

5. Teko ea Khatello le ho Lutla

5.1 Morero

Ho netefatsa hore valve ha e na ho dutla tlasa kgatello e lekantsweng.

5.2 Mekhoa ea Kamohelo

'Mele oa valve le likarolo tsohle tse jarang khatello ha lia lokela ho ba le tšenyo efe kapa efe ea sebopeho, ho fetoha ha kamehla, kapa ho lutla.

5.3 Lintho tsa Teko

Teko ea Matla a Khetla: Teko ea Hydrostatic ka khatello e lekantsoeng ka makhetlo a 1.5, nako ea ho tšoara ≥ metsotso e 2.

Teko ea ho Tiisa: Teko ea ho tiisa pele le morao ka khatello e lekantsoeng ka makhetlo a 1.1.

Teko ea ho Tiea ha Moea: Fumana ho lutla ha moea o monyenyane ka ho sebelisa moea kapa naetrojene ho 0.6 MPa.

Tekanyetso ea ho se lutle: E latela litlhoko tsa API 598 / ISO 5208.

6. Teko ea Torque e Sebetsang

6.1 Morero

Ho netefatsa hore na torque ea ho bula le ho koala e fihlela maemo a tloaelehileng 'me e ka har'a litlhoko tsa moralo, ho netefatsa hore yuniti ea drive e ea tšoana.

Mokhoa oa Teko

E lekanngoa ka ho sebelisa li-wrenches tsa torque le li-torque tse kang li-actuator tsa motlakase; bapisa torque ea moralo le torque e lekantsoe.

7. Tlhahlobo ea Pono le ea Matšoao

7.1 Morero

Ho netefatsa boleng ba ponahalo le litlhaloso tsa ho tšoaea.

7.2 Lintho tsa Teko

Ha ho na mafome a tšepe, slag ea ho tjheseletsa, matheba a oli, kapa litšila tse ling ka hare.

Ha ho mapetso, li-burrs, kapa mafome. Boreledi ba bokaholimo le botsitso ba 'mala. Tlhahisoleseding ea lebitso la poleiti (mohlala, tekanyo ea khatello, thepa, motsu oa tataiso ea phallo) e hlakile, e feletse, 'me e sireletsehile.

8. Teko ea Ts'ebetso

8.1 Morero

Ho netefatsa ts'epo le ts'ebetso ea phallo ea valve.

8.2 Lintho tsa Teko

Ho buloa le ho koaloa ha poleiti ea valve

Ho nepahala ha boemo ba valve

Tekanyo ea coefficient ea ho hanyetsa phallo (boleng ba Cv)

Tsela e tsitsitseng ea phallo ea mokelikeli

9. Tlhahlobo ea ho Qetela le Tlhahlobo ea Feme

9.1 Morero

Ho fumana ka botlalo hore na sehlahisoa se tšoaneleha ebile se loketse ho romelloa.

9.2 E kenyeletsa

Tlhahlobo ea lirekoto tsa liteko

Ho khomaretsa setifikeiti sa ho lumellana le mabitso a liteko

Hore na sephutheloana se sireletsa ka katleho khahlanong le tšenyo nakong ea lipalangoang, le hore na ho na le likheo tse sireletsang sefahlehong sa flange le lipheletsong tse nang le khoele.

Nako ea poso: Mphalane-28-2025