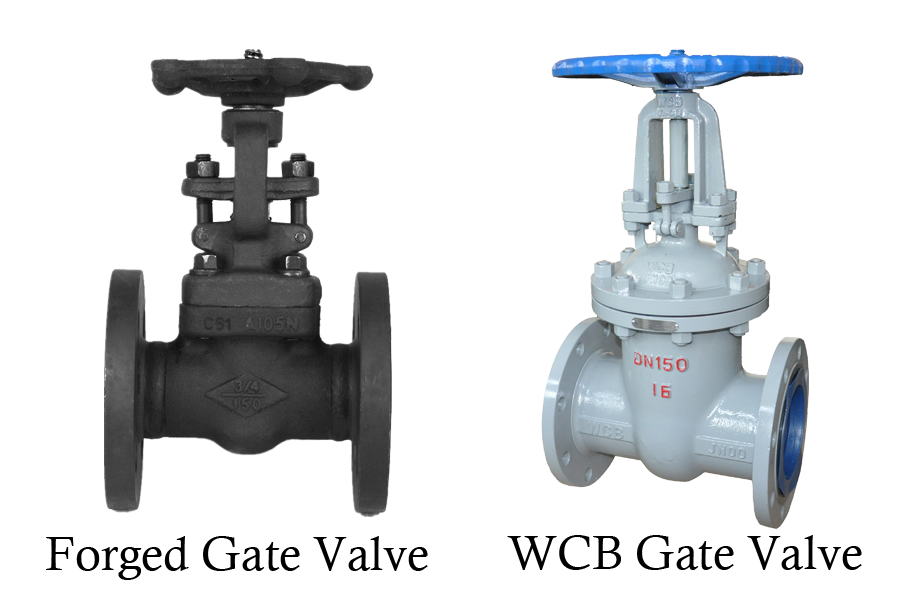

Haeba o ntse o qeaqea hore na o tla kgetha di-valve tsa heke tsa tshepe tse entsweng ka forged kapa di-valve tsa heke tsa tshepe e entsweng ka cast (WCB), ka kopo sheba fektheri ya di-valve tsa zfa ho hlahisa dipharologanyo tse kgolo pakeng tsa tsona.

1. Ho betla le ho lahla ke mekhoa e 'meli e fapaneng ea ho e lokisa.

Ho lahla: Tšepe e futhumatsoa ebe ea qhibilihisoa ebe e tšeloa ka har'a hlobo ea lehlabathe kapa hlobo. Kamora ho pholile, e tiea hore e be ntho. Masoba a moea a hlahisoa habonolo bohareng ba sehlahisoa.

Ho betla: Haholo-holo ho sebelisoa mekhoa e kang ho betla ka hamore mochesong o phahameng ho etsa tšepe hore e be mosebetsi o nang le sebopeho le boholo bo itseng boemong ba polasetiki, le ho fetola litšobotsi tsa eona tsa 'mele.

2. Phapang tshebetsong pakeng tsa di-valve tsa heke tse entsweng leLi-valve tsa heke tsa WCB

Nakong ea ho betla, tšepe e fetoloa polasetiki, e leng se etsang hore e hloekise lithollo, kahoo hangata e sebelisoa tlhahisong e se nang letho ea likarolo tsa bohlokoa. Ho betla ho na le litlhoko tsa thepa e lokelang ho sebetsoa. Ka kakaretso, tšepe e entsoeng ka tšepe, aluminium, jj. li na le thepa e betere ea ho betla. Ho betla ha ho na melemo e mengata ea ho betla, empa ho ka hlahisa likarolo tse nang le libopeho tse rarahaneng, kahoo hangata ho sebelisoa tlhahisong e se nang letho ea likarolo tse tšehetsang tse sa hlokeng thepa e phahameng ea mechini.

2.1 Khatello

Ka lebaka la phapang ea thepa ea thepa, li-valve tsa tšepe tse entsoeng ka maiketsetso li ka mamella matla a maholo a tšusumetso, 'me polasetiki ea tsona, ho tiea le thepa e meng ea mechini li phahame ho feta tsaLi-valve tsa WCBKa hona, e ka sebelisoa maemong a phahameng a ho sebetsa a khatello. Maemo a khatello a sebelisoang hangata a li-valve tsa tšepe tse entsoeng ka tšepe ke: PN100; PN160; PN250; PN320; PN400, 1000LB ~ 4500LB. Likhatello tse tloaelehileng tse sebelisoang hangata tsa li-valve tsa WCB ke: PN16, PN25, PN40, 150LB ~ 800LB.

2.2 Bophara ba lebitso

Kaha ts'ebetso ea ho betla e na le litlhoko tse phahameng holim'a hlobo le lisebelisoa, bophara ba li-valve tse betliloeng hangata bo ka tlase ho DN50.

2.3 Bokhoni ba ho thibela ho dutla ha metsi

Ho latela ts'ebetso ka boeona, ho lahla ho na le monyetla oa ho hlahisa lesoba nakong ea ts'ebetso. Ka hona, ha ho bapisoa le ts'ebetso ea ho qapa, bokhoni ba ho thibela ho lutla ha li-valve tsa cast ha bo botle joaloka ba li-valve tse entsoeng ka forged.

Ka hona, liindastering tse ling tse nang le litlhoko tse phahameng tsa thibelo ea ho lutla, tse kang khase, khase ea tlhaho, peterole, lik'hemik'hale le liindasteri tse ling, li-valve tsa tšepe tse entsoeng ka maiketsetso li 'nile tsa sebelisoa haholo.

2.4 Ponahalo

Li-valve tsa WCB le li-valve tsa tšepe e entsoeng ka maiketsetso li bonolo ho li khetholla ka ponahalo. Ka kakaretso, li-valve tsa WCB li na le ponahalo ea silevera, ha li-valve tsa tšepe e entsoeng ka maiketsetso li na le ponahalo e ntšo.

3. Liphapang masimong a kopo

Khetho e tobileng ea li-valve tsa WCB le li-valve tsa tšepe tse entsoeng ka mokhoa o qhibilihisitsoeng e itšetlehile ka tikoloho ea mosebetsi. Ho ke ke ha hlalosoa ka kakaretso hore na ke masimo afe a sebelisang li-valve tsa tšepe tse entsoeng ka mokhoa o qhibilihisitsoeng le hore na ke masimo afe a sebelisang li-valve tsa WCB. Khetho e lokela ho ipapisa le tikoloho e itseng ea mosebetsi. Ka kakaretso, li-valve tsa WCB ha li hane le asiti le alkali 'me li ka sebelisoa feela liphaepheng tse tloaelehileng, ha li-valve tsa tšepe tse entsoeng ka mokhoa o qhibilihisitsoeng li ka mamella khatello e phahameng 'me li ka sebelisoa lifekthering tse ling tse nang le mocheso o phahameng, joalo ka lifeme tsa motlakase le lifeme tsa lik'hemik'hale. Valve ea sehlopha.

4. Theko

Ka kakaretso, theko ea li-valve tsa tšepe tse entsoeng ka maiketsetso e phahame ho feta ea li-valve tsa WCB.

Nako ea poso: Pulungoana-20-2023