A serurubele se kolokileng ka botlaloe na le sebopeho se nang le mela ka ho feletseng ka har'a 'mele oa valve. Moralo ona o etselitsoe lisebelisoa tse hananang le kutu.

"Ka botlalo" ho bolela hore ha se feela disc e koetsoeng ka ho feletseng, empa hape le setulo se koetsoe ka ho feletseng, ho netefatsa hore ho itšehla thajana ho feletseng pakeng tsa mecha ea phatlalatso le tšepe.

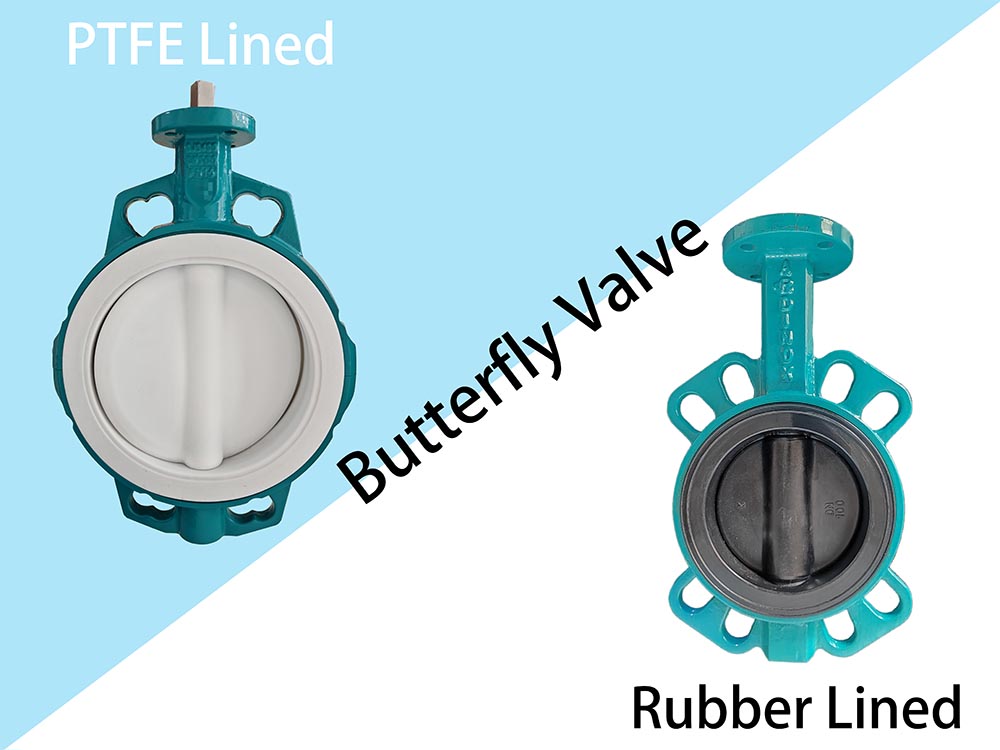

1. Lisebelisoa tse peli tse tloaelehileng tsa lesela

a. PTFE (polytetrafluoroethylene, perfluoroplastic) lesela la serurubele valve

b. Rubber lesela la serurubele valve

| Mofuta oa thepa: | Polytetrafluoroethylene (PTFE) lesela | Lesela la rabara (mohlala, EPDM, Viton, NBR) |

| Mokhoa oa ho lekanya | Molten PTFE/PFA e tšeloa ka har'a groove ea dovetail holim'a 'mele / disc, ho fihlela tlamahano e se nang moeli. | Ebe e ts'oaroa ka kotloloho (e phekotsoe mocheso) holim'a tšepe, e etsa tiiso e tiileng, e bohlokoa. |

| Likarolo tsa mantlha | - Khanyetso e ntle ea kutu (e hanana le hoo e batlang e le li-acids tsohle, metheo le li-solvents tsa organic) - Ho hanyetsa mocheso o phahameng (mocheso o tsoelang pele oa ho sebetsa ho fihlela ho 180°C) - Coefficient e tlase ea likhohlano le thepa e se nang thupa, e loketseng mecha ea litaba ea bohloeki bo phahameng

| - Elasticity e ntle haholo le ts'ebetso e ntle ea ho tiisa (ho bonolo ho fihlella ho lutla ha zero) - Theko e tlaase le khanyetso e ntle ea ho apara bakeng sa mecha ea litaba e sa senyang - Ho hanyetsa mocheso o tlase (hangata -20°C ho isa ho 180°C, ho latela mofuta oa rabara)

|

| Media e sebetsang | Li-acid tse matla (joalo ka sulfuric acid le hydrochloric acid), li-bases tse matla, li-solvents, maro a hloekileng. | metsi, metsi a litšila, li-acid tse fokolang le metheo, li-slurries, le mecha ea phatlalatso ea lijo |

| Lisebelisoa tse Tloaelehileng | Indasteri ea Lik'hemik'hale (phetisetso ea asiti le alkali), Indasteri ea Meriana (phetiso ea thepa e hloekileng haholo) | Phekolo ea Metsi (phekolo ea metsi a litšila, metsi a pompo), Litsamaiso tsa HVAC, Indasteri ea Lijo le Lino, Merafo (ho fetisoa ha slurry) |

2. Mehato e qaqileng ea Ts'ebetso ea PTFE-lined Valve Discs

2.1 Tokiso ea Metal Disc

a .. Lahlela kapa u kenye mokokotlo oa disc oa tšepe, ho netefatsa hore bokaholimo bo hloekile ebile ha bo na oli le tšilafalo.

b.. Khaola li-grooves (sebopeho sa dovetail) holim'a metsi a mantlha ho fana ka lintlha tsa ankora bakeng sa ente ea PTFE le ho e thibela ho oa.

2.2 PTFE Powder Molding and Preforming

a. Beha palo e baliloeng ka hloko ea PTFE phofo (kapa premix) ka har'a hlobo, kenya tšepe ea tšepe ea serurubele ea tšepe, ebe u eketsa phofo ea PTFE.

b. Butle-butle kenya vacuum (exhaust) le khatello ( compression kapa isostatic pressing) ho etsa embryo e tala. Isostatic molding: Koahela hlobo ka metsing 'me u sebelise khatello e tšoanang ka mahlakoreng' ohle (khatello ea metsi) ho etsa bonnete ba hore ho na le sebopeho se ts'oanang le se teteaneng (porosity e tlaase ho <1%).

2.3 Ho Sintering le Pheko

a. Beha embryo e tala ka ontong 'me u chese ka 380 ° C bakeng sa lihora tse 5-24 (butle-butle eketsa mocheso ho qoba mapetsong).

b. Butle-butle ho pholile mocheso oa kamore ho lumella PTFE hore e khanye le ho kopanya le mokokotlo oa tšepe, ho etsa seaparo se se nang moeli (botenya bo laoloang ho ba 3-10mm, bo lokisoa ho ea ka maemo a vacuum).

2.4 Mechine le ho Qetella:

Sebelisa mochine oa lathe kapa oa CNC ho kenya li-diameter tse ka hare le tse ka ntle ho etsa bonnete ba hore disc le setulo li lumellana hantle (ho mamellana ho thata, mohlala, ± 0.01mm).

2.5 Tlhahlobo le Teko ea Boleng:

a. Tekanyo ea Botenya: Etsa bonnete ba hore lesela le tlase la 3mm, kapa joalo ka ha le etselitsoe.

b. Tlhahlobo ea Spark: 35,000 volts bakeng sa teko ea ho tiea (ha ho na karohano e bontšang kamohelo).

c. Teko ea Vacuum / Matla: E etsisa maemo a ts'ebetso ho lekola ho lutla le ho kenella (ho latela EN 12266-1 kapa API 598).

d. Teko ea Conductivity (boikhethelo): Ho hanyetsa bokaholimo <10⁶Ω bakeng sa lits'ebetso tse thibelang ho phatloha.

3. Mehato e qaqileng ea Ts'ebetso ea Li-discs tse nang le EPDM

3.1 Tokiso ea Metal Disc

a. Lahlela kapa u kenye mokokotlo oa tšepe ho netefatsa sebaka se hloekileng, se se nang mafome.

b. Lehlabathe kapa ka lik'hemik'hale etch bokaholimo (roughness Ra 3-6μm) ho khothalletsa EPDM adhesion.

3.2 EPDM Compound Kopo le Preforming

Motsoako oa EPDM o sa phekolehang (letlapa kapa mokelikeli) o kenngoa ka har'a hlobo, o pota-potile mokokotlo oa tšepe. U sebelisa ho bopa ha compression kapa ho tšela, ka ho lekana aba motsoako holim'a sepakapaka sa valve ho etsa 'mele o motala. Boloka botenya ba limilimithara tse 2-5, ho netefatsa hore ho na le tšireletso ho pota-potile li-disk.

3.3 Ho phekola

'Mele o motala o kenngoa ka autoclave' me o futhumetse ka mouoane kapa moea o chesang (150-180 ° C, khatello> 700 psi, bakeng sa lihora tsa 1-4).

Mokhoa oa ho folisa o kopanya le ho phekola EPDM, ka lik'hemik'hale le ka mochine o tlamahanngoa le motheo oa tšepe ho etsa lesela le se nang seam, la karolo e le 'ngoe. Eketsa mocheso butle ho qoba lipululana tsa moea kapa mapetsong.

3.4 Ho Qetella Mochini

Ka mor'a hore u pholisoe, fokotsa likarolo tse ka hare le tse ka ntle u sebelisa lesela la CNC ho netefatsa hore disc le setulo li lumellana hantle (mamello ± 0.05 mm). Tlosa rabara e feteletseng 'me u hlahlobe boemo bo ka thōko (ho roala ha Ni-Cu ke boikhethelo bakeng sa ho ntlafala ha ho apara).

3.5 Tlhahlobo ea Boleng le Teko

a. Teko ea botenya le ho khomarela: Tekanyo ea botenya ba Ultrasonic (bonyane 2mm); Teko ea Tensile (matla a peeletso> 10 N/cm).

b. Netefatso ea Ts'ebetso: Teko ea Tiiso ea Bubble e Tight (API 598 e tloaelehileng); Teko ea Khatello / Vacuum (PN10-16, ho hanyetsa khatello e mpe).

c. Teko ea Lik'hemik'hale / Botsofali: Ho qoelisoa ka mecha ea litaba ea acid le alkaline, ho hlahloba ho atolosoa <5%; Botsofali bo phahameng ba mocheso (120°C, 72h).

4. Tataiso ea Khetho

PTFE linings li loketse mecha ea litaba e senyang haholo (e kang li-acids, alkalis, le solvents), ha li-EPDM linings li loketse metsi, mecha ea litaba e bonolo (e kang metsi le dilute acid). Beha pele ho lumellana ha lik'hemik'hale, mocheso, khatello, le litšenyehelo ho ntlafatsa ts'ebeliso. Zhongfa Valve e etsa li-valve tsa serurubele tse nang le mela e felletseng tse nang le likhetho tsa li-wafer, flange le mekotla. Ka kopo ikopanye le rona ka lipotso leha e le life.

Nako ea poso: Oct-28-2025