Sehloohong se fetileng, re buile ka li-valve tsa heke le tsa globe, kajeno re fetela ho li-valve tsa serurubele le li-valve tsa ho hlahloba, tse atisang ho sebelisoa ho hloekisa metsi.

1. Butterfly Valve.

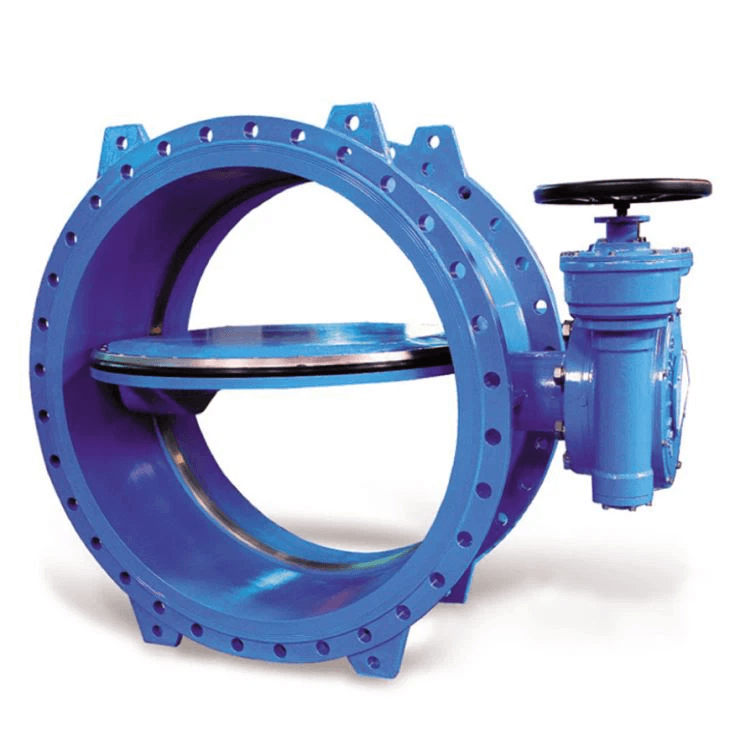

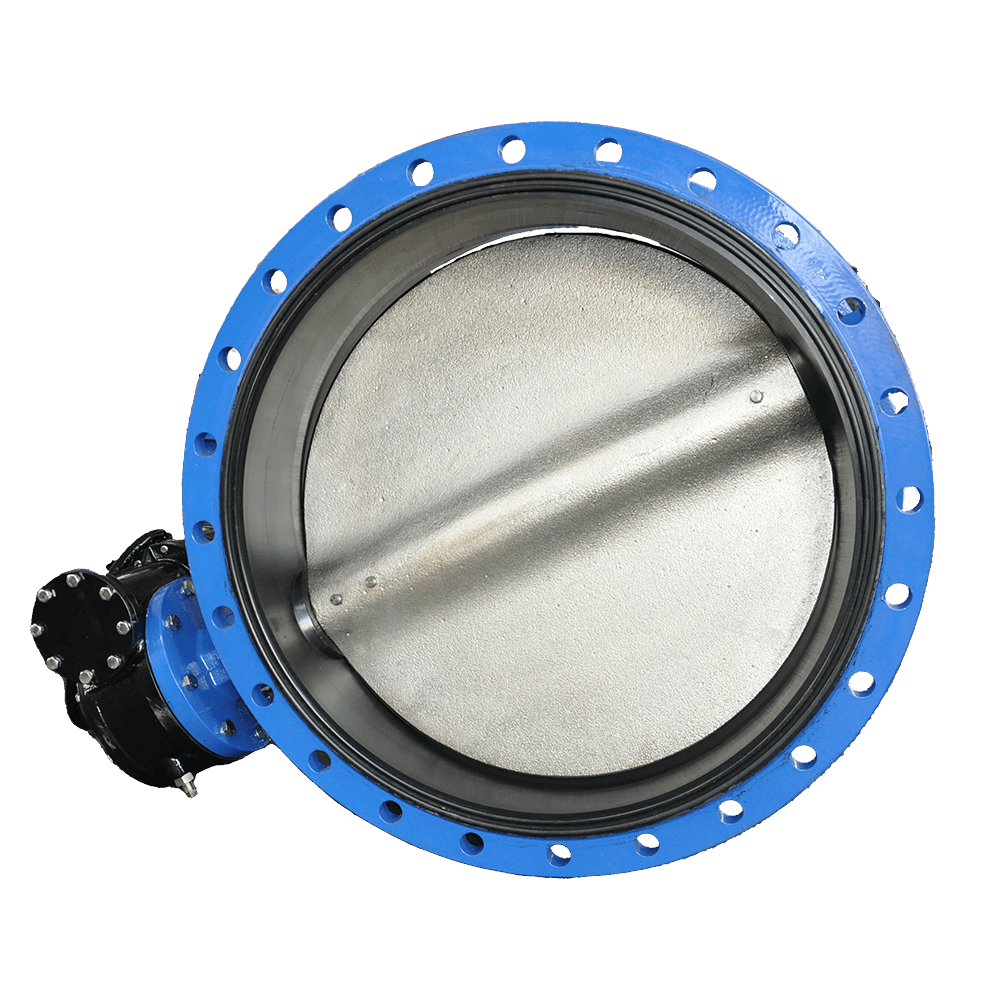

Butterfly valveke valve ea rotary e sebelisang disc (eo hape e tsejoang e le poleiti ea serurubele) setho se bulang le se koalang ho potoloha 90 ° kapa hoo e ka bang 90 ° ho bula le ho koala mocha.Ho tsamaea ha li-valve tsa serurubele ho ntse ho hlakola, kahoo li-valve tse ngata tsa serurubele li ka sebelisoa bakeng sa mecha ea litaba e nang le likaroloana tse tiileng tse emisitsoeng.

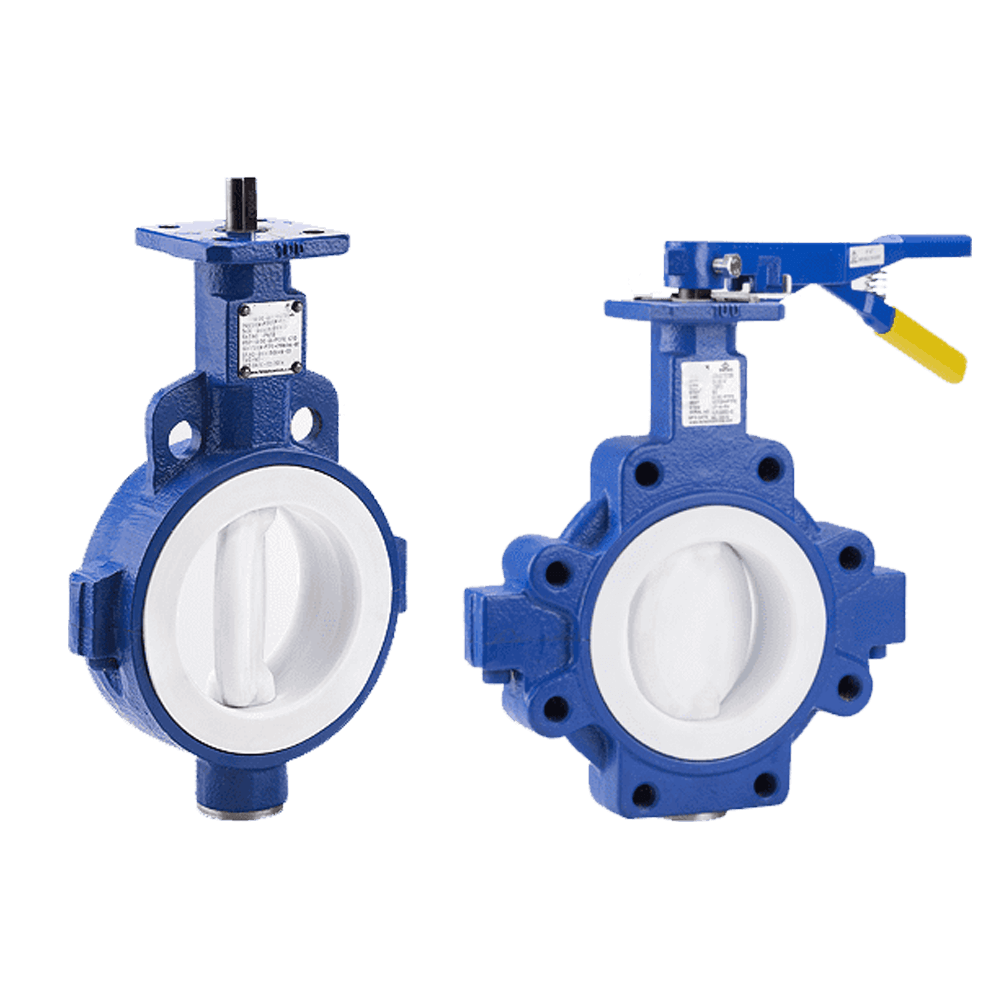

Li-valve tsa serurubele tse sebelisoang ka tloaelo li kenyelletsa li-valve tsa wafe le li-flanged butterfly.Serurubele sa mofuta oa serurubele se sebelisoa ho hokahanya belofo pakeng tsa liphaephe tse peli tse nang le liboutu tsa stud, le belofo ea mofuta oa serurubele se nang le flange holim'a belofo, 'me li-flange lipheletsong tse peli tsa belofo li hokahane le phala flange ka liboutu.

Likaroloana:

1.Boholo bo nyane, bolelele bo bokhutšoane, sebopeho se bonolo le boima bo bobebe.

2. Ho bonolo ho sebetsa, ho bula le ho koala ka potlako, ho hlokahala feela ho potoloha disk 90 ° ho bula le ho koala.

3. Ho tiisa hantle le ts'ebetso ea tokiso.Hobane rabara e sebelisoa e le lesale la ho tiisa, khatello le ho tiea li ntle (ke hore, e ke ke ea thatafala), kahoo ts'ebetso ea ho tiisa e ntle..Leqhubu la valve le ka buloa pakeng tsa 15 ° le 70 °, 'me le ka etsa taolo e matla ea ho phalla.

4. Torque e nyenyane ea ho sebetsa le ho hanyetsa metsi.Ho ea ka litekanyo, ho hanyetsa mokelikeli oa li-valve tsa serurubele ho tlase ho feta mefuta e meng ea li-valve haese li-valve tsa bolo.

5. Ka lebaka la ho fokotsa thepa ea ho tiisa, khatello ea ts'ebetso le mocheso oa mocheso oa ho sebetsa oa valve ea serurubele e batla e le nyenyane.

2.Check Valofo

Tšebeliso le litšobotsi:

Hlahloba valveke valve e sebelisetsoang ho thibela ho khutlela morao ha mecha ea litaba ka har'a pipeline, e bula ha metsi a phalla ka tlaase 'me a koala ka tsela e iketsang ha sehare se phalla morao.Ka kakaretso e sebelisoang liphaepheng ha e lumelle seaplane ho phalla ka lehlakoreng le fapaneng, e le ho thibela ho khutlela morao ha tšenyo e bohareng ea lisebelisoa le likarolo.Ha pompo e emisa ho sebetsa, u se ke ua etsa hore pompo ea rotary e fetohe.Ka lipeipi, hangata hlahloba li-valve le li-valve tse koetsoeng tse sebelisoang ka letoto.Sena se bakoa ke ho koala ho futsanehileng ha valve ea ho hlahloba, ha khatello ea mecha ea litaba e le nyenyane, ho tla ba le karolo e nyenyane ea ho tsoa ha mecha ea litaba, tlhokahalo ea li-valve tse koetsoeng ho tiisa hore ho koaloa ha pipeline.Belofo e ka tlase e boetse e le valve ea ho hlahloba, e tlameha ho qoelisoa ka metsing, e kentsoeng ka ho khetheha ka har'a pompo e ke ke ea itšehla thajana kapa ha ho na vacuum pumping water suction pipe ka pele.

Li-valve tsa kalafo ea metsi ho hloleha ho tloaelehileng le mehato

Valve ts'ebetsong ea liphaephe ka nako e itseng, ho tla ba le mefokolo e fapaneng.Ntlha ea pele, palo ea likarolo tse amanang le ho hlophisoa ha valve, likarolo tse ngata ke ho hlōleha ho tloaelehileng.Taba ea bobeli, ka moralo oa li-valve, ho etsa, ho kenya, maemo a ts'ebetso, melemo ea tlhokomelo le mefokolo.Li-valve tse tloaelehileng tse sa khannoeng ka matla li hloleha tse tloaelehileng li arotsoe ka mekhahlelo e mene.

1.Ho hloleha ha phetiso

Ho hloleha ha sesebelisoa sa phetisetso hangata ho bonahala ha valve stem jamming, ts'ebetso e sa fetoheng kapa valve e sa sebetse.Mabaka ke: valve e koetsoe nako e telele ka mor'a mafome;ho kenya le ho sebetsa ha tšenyo e sa lokelang ho likhoele tsa stem kapa linate tsa stem;heke e petelitsoe 'meleng oa valve ke lintho tse tsoang linaheng tse ling;heke hangata halofo-butsoe 'me halofo-e koetsoe mmuso, ka metsi kapa liphello tse ling lebisa ho stems screws le stem nut terata mesalignment, loosening, loma ketsahalo;khatello ea ho paka e thata haholo, e tšoereng kutu;kutu e phahamisoa kapa ka ho koaloa ha likarolo tse petelitsoeng.Tlhokomelo e lokela ho ba likarolo tsa koloi tse tlotsitsoeng.Ka thuso ea wrench, le ho tlanya ka bonolo, o ka felisa ts'ebetso ea ho jamming, topping;ho emisa ho lokisa metsi kapa ho fetola valve.

2.Ho phatloha ha 'mele oa valve ho senyehile

Mabaka a senyehileng a ho phatloha ha 'mele oa valve: ho hanyetsa ho bola ha thepa ea valve ho fokotseha;phepelo ea motheo ea bolulo;khatello ea marang-rang ea pipe kapa liphetoho tse fapaneng tsa mocheso;hamore ea metsi;koala ts'ebetso e sa lokelang ea valve joalo-joalo.E lokela ho tlosa lisosa tsa ka ntle hang-hang 'me e nkele mofuta o tšoanang oa likarolo kapa li-valve.

3. Ho lutla ha valve

Ho lutla ha valve ho bonahala e le: ho lutla ha motheo oa valve;ho tsoa ha gland;flange gasket dutla.Lisosa tse tloaelehileng ke: ho roala ha kutu (valve shaft), corrosion spalling, likoti tse koalang holim'a metsi, ho ebola;tiiso ea botsofali, leakage;liboutu tsa tšoelesa, liboutu tsa flange li hlephile.Tlhokomelo ea ho eketseha, sebaka sa ho tiisa;tlosa nate e ncha ho lokisa boemo ba bolt e tiisang.

Ho sa tsotellehe hore na ke ho hlōleha ha mofuta ofe haeba ho lokisoa ho tloaelehileng, tlhokomelo e sa nakong, e ka baka litšila tsa metsi, kapa ho hobe le ho feta, e baka hore tsamaiso eohle e holofetse.Ka hona, basebeletsi ba tlhokomelo ea li-valve ba tlameha ho ba ka lisosa tsa ho hlōleha ha valve ho etsa mosebetsi o motle, taolo le ts'ebetso ea litsebo tse nang le tsebo le tse nepahetseng, phekolo e nakong le ea makhaola-khang ea mefokolo e fapaneng ea tšohanyetso, ho sireletsa ts'ebetso e tloaelehileng ea marang-rang a phekolo ea metsi.

4. valve ea ho bula le ho koala ha e ntle

Ho bula le ho koala ts'ebetso e mpe bakeng sa valve ha e bulehe kapa e koetsoe, valve ha e khone ho sebetsa ka mokhoa o tloaelehileng.Mabaka ke: kutu ea kutu ea valve;heke e koetsoeng kapa heke e koetsoe ka nako e telele boemong ba mafome;ho tloha hekeng;lintho tse tsoang linaheng tse ling tse khomaretsoeng ka holim'a ho tiisa kapa ho tiisa groove;likarolo tsa phetiso li apara, ho jamming.Ho kopana le tlhokomelo ea boemo bo ka holimo, likarolo tsa phetiso ea lubrication;ka makhetlo a mangata ho bula le ho koala valve le phello ea hydrodynamic ea lintho tse tsoang linaheng tse ling;phetoho ea valve.